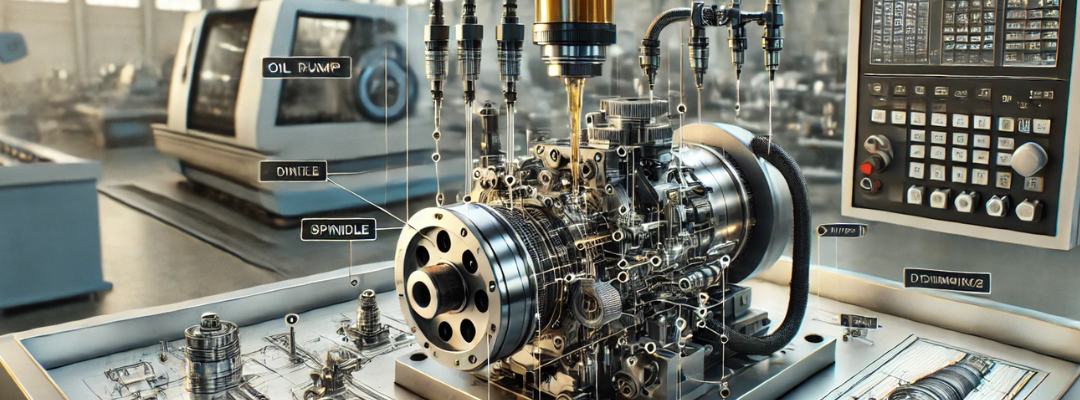

A lubrication pump in a CNC (Computer Numerical Control) machine plays a critical role in maintaining the smooth operation and longevity of the machine. Its primary function is to deliver a controlled and consistent supply of lubricant (typically oil) to key moving parts such as bearings, ball screws, and guideways. Here are the main functions of the lubrication pump in a CNC machine:

- Reducing Friction: The lubricant minimizes friction between moving components, preventing excessive wear and tear on the machine parts.

- Heat Dissipation: By reducing friction, the lubricant helps dissipate heat generated during machine operation, keeping the machine parts cooler and enhancing performance.

- Preventing Corrosion: The lubricant creates a protective layer on metal surfaces, preventing rust and corrosion, especially in humid environments.

- Ensuring Precision: Regular lubrication helps maintain the precision and accuracy of the CNC machine by ensuring that the moving parts function smoothly without sticking or unnecessary resistance.

- Prolonging Machine Life: Proper lubrication reduces the chances of mechanical failure and extends the lifespan of the CNC machine by keeping critical components in good condition.

The lubrication pump is usually automated and designed to operate at regular intervals, ensuring the machine remains properly lubricated without manual intervention.

Recent Comments