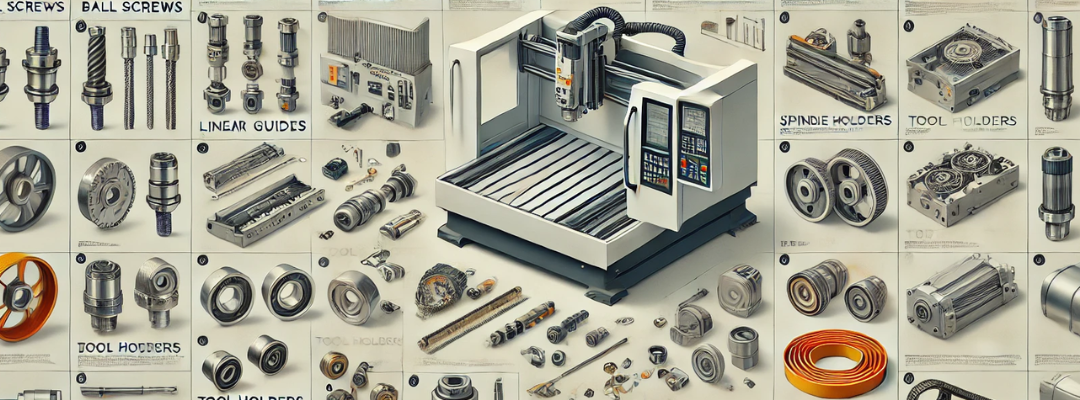

A CNC machine consists of numerous parts that work together to perform precise machining operations. Below is a general list of key spare parts commonly used in CNC machines:

1. Mechanical Components

- Ball Screws: Convert rotational motion into linear motion with high precision.

- Linear Guideways: Provide smooth linear motion for the machine’s axes.

- Bearings: Support rotating parts like spindles and ball screws.

- Couplings: Connect motors to ball screws or other machine elements.

- Tool Holders (e.g., BT, HSK, CAT): Hold cutting tools in place on the machine’s spindle.

- Collets: Grip the tool in the spindle or tool holder.

- Spindle Bearings: Ensure smooth rotation of the spindle.

2. Electrical Components

- Servo Motors: Drive the machine’s axes with precise motion control.

- Stepper Motors: Control the incremental movement of the machine.

- Spindle Motor: Powers the spindle, enabling the cutting tool to rotate.

- Encoders: Provide feedback on the position of moving parts.

- Limit Switches: Detect the limit of motion to prevent overtravel of machine axes.

- Proximity Sensors: Detect the position of machine parts or tools.

- Power Supply Units: Provide power to various machine components.

- Cables and Connectors: Connect various electrical components for power and signal transmission.

3. Hydraulic/Pneumatic Components

- Hydraulic Pumps: Control the movement of heavy parts in some CNC machines.

- Solenoid Valves: Control the flow of air or fluid in hydraulic or pneumatic systems.

- Pneumatic Cylinders: Provide movement for components such as tool changers.

4. Control System Components

- CNC Controller Unit: The brain of the CNC machine, controlling all operations and processing G-code.

- Control Panel: Where operators input commands and control the machine manually.

- Display Monitor: Shows machine parameters, operating status, and CNC program details.

- Keypads or Touchscreen Interfaces: For operator input to control the machine functions.

5. Cooling and Lubrication Components

- Coolant Pumps: Supply cutting fluid to the tool and workpiece for cooling.

- Lubrication Pumps: Deliver oil or grease to moving parts for smooth operation.

- Coolant Nozzles: Direct coolant flow to the cutting zone.

6. Tooling and Workholding Components

- Vices and Clamps: Hold the workpiece securely in place.

- Chucks: Attach to the spindle to hold larger or specific types of tools.

- Fixture Plates: Custom plates designed to hold workpieces in place during machining.

- Tool Turrets (for lathes): Hold multiple tools and rotate them into position as needed.

7. Miscellaneous Components

- Tool Probes: Measure tool length and diameter for precise tool positioning.

- Workpiece Probes: Measure the workpiece position and alignment on the machine table.

- Filters (Coolant and Air): Keep the coolant and machine’s air systems clean.

- Fan Units: Cool down the machine components like the control unit or motors.

- Belts: Transmit power from the motors to other moving parts.

- Fuses and Circuit Breakers: Protect the machine’s electrical system from overloads.

Having these spare parts on hand can help minimize downtime and ensure the CNC machine operates efficiently and with precision.

Recent Comments