Delta Elevator Control

MH300-L

Delta‘s MH300-L is a compact drive for elevators that features several elevator specific functions, such as open loop IM motor control and EPS/ARD. Other built-in functions include EMC filter, brake chopper, I/O extension slot, USB port and 5k steps PLC capacity. With drive size reduced up to 40%, the MH300-L series is compact, easy to set up and wire, and efficient and stable.

IED-S series

The IED-S Series offers an integrated elevator drive and control solution which inherits Delta advanced vector control technologies and provides precise control of both IM & PM motors for a safe and smooth ride.

Its built-in elevator control technology and smart design minimizes the time and space required for installation and adjustment.

The IED-S Series complies with international safety standards (UL/CE) to ensure elevator passenger safety. Its compact design is durable and supports versatile encoding types. With the optional Active Front End AFE2000 Series and the Power Regenerative Unit REG2000 Series, the IED-S enables power regeneration and energy-savings, offering an optimal elevator drive control solution.

RE2000 Series

A traditional drive system used for inertia load work generally performs rapid deceleration, braking and positioning. When its motor is in generator mode it produces large amounts of regenerative energy that must be consumed to maintain a stable DC bus voltage and safe operation. The traditional method to solve the regenerative energy problem is to install a brake resistor. While it is easy to install and is low cost, it takes up a large amount of space and requires installing additional devices to dissipate the heat. This method provides limited efficiency and wastes the regenerative energy.

Delta’s REG2000 series is capable of collecting and converting your system’s regenerative energy into reusable electricity for the ultimate in energy savings. The installation process is as simple as installing a brake resistor, but with only half the size and better efficiency. The REG2000 is your best green energy solution for power regeneration.

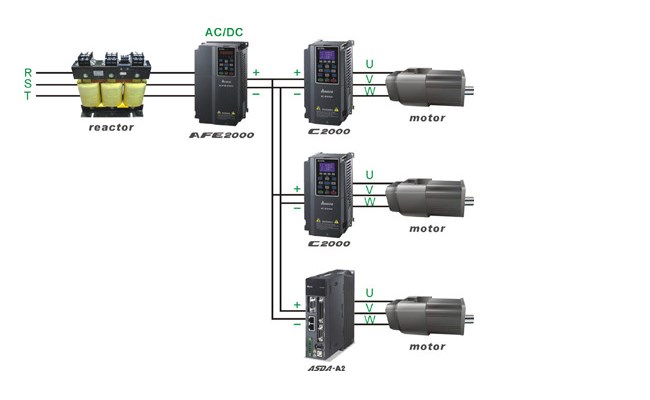

AFE2000 series

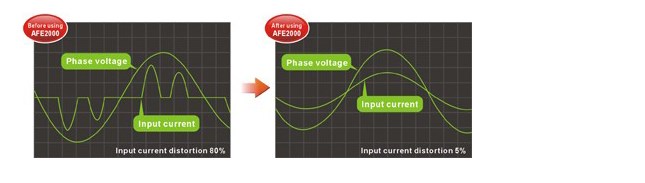

Active Front End (AFE) is a controllable rectifier with advantages such as providing bidirectional power exchange between AC and DC power and regenerating reusable power to the mains to reduce the cost of power. The AFE uses PWM modulation to greatly reduce distinctive peaks of current and form perfect sine wave current. The power factor is corrected up to 1—the ratio between load capacity and power capacity is 1:1.In addition, the AFE eliminates high order harmonics, provides very low harmonic current THD<5% while improving the power factor, which allows you to save the cost of purchasing additional electrical equipment for better power quality,. The AFE also offers stable power quality unaffected from mains power fluctuations and can be applied to a serial connection.

Incorporating years of experience in AC motor drive development, Delta introduces the innovative AFE2000. This unit is designed for a wide range of applications and it achieves outstanding energy saving results. The AFE2000 does not dissipate excess heat into the air but converts it into reusable power that can be supplied back to the mains. The AFE2000 is yet another Delta product that contributes to improving efficiency and productivity and that fulfills our mission “to provide innovative, clean and efficient energy solutions for a better tomorrow”.

You must be logged in to post a review.

Reviews

There are no reviews yet.